OSHA - Electrical

OSHA - Electrical

Course Description

This course provides an overview of useful electrical terminology, as well as instruction regarding types of electrical injuries, hazards, protective devices and examples of OSHA electrical requirements.

Accreditation Information: KLA Education Services LLC is accredited by the State of California Board of Registered Nursing, Provider # CEP16145.

Course Certification: Once you have completed this course, click on the “Print Certificate” option below to save or print your CE course certification. If you are not yet registered in a course plan with IvyLeagueNurse, please complete the registration and payment process so that you are able to log into your account and fully obtain your course certificate. Our affordable and unlimited one-year CEU plan starts at just $19.99.

Print Certificate Print Course

Course Objectives

Upon completion of this course, the course participant will be able to:

- Describe four types of injuries that may result from

- contact with electricity.

- List the three main electrical hazards that may be

- encountered at a worksite.

- Discuss at least three methods of protection from

- electrical hazards.

- Describe the function of a ground fault circuit

- interrupter (GFCI).

- Name at least three warning signs or clues that an

- electrical hazard exists.

Course Content

Introduction

An average of one worker is electrocuted on the job every day.

The four main types of electrical injuries are:

- Electrocution (death due to electrical shock)

- Electrical shock

- Burns

- Falls

Electrical Terminology

- Current – the movement of electrical charge

- Resistance – opposition to current flow

- Voltage – a measure of electrical force

- Conductors – substances, such as metals, that have little resistance to electricity

- Insulators – substances, such as wood, rubber, glass, and bakelite, that have high resistance to electricity

- Grounding – a conductive connection to the earth which acts as a protective measure

Electrical Shock

- Received when current passes through the body

- Severity of the shock depends on:

- Path of current through the body

- Amount of current flowing through the body

- Length of time the body is in the circuit

- LOW VOLTAGE DOES NOT MEAN LOW HAZARD

Dangers of Electrical Shock

- Currents greater than 75 mA* can cause ventricular fibrillation (rapid, ineffective heartbeat)

- Will cause death in a few minutes unless a defibrillator is used

- 75 mA is not much current – a small power drill uses 30 times as much

Defibrillator in use

*mA = milliampere = 1/1000 of an ampere

How Electrical Shocks Occur

-

When two wires have different potential differences (voltages), current will flow if they are connected together

-

In most household wiring, the black wires are at 110 volts relative to ground

-

The white wires are at zero volts because they are connected to ground

-

-

If you come into contact with an energized (live) black wire, and you are also in contact with the white grounded wire, current will pass through your body and YOU WILL RECEIVE A SHOCK

-

If you are in contact with an energized wire or any energized electrical component, and also with any grounded object, YOU WILL RECEIVE A SHOCK

-

You can even receive a shock when you are not in contact with a ground

-

If you contact both wires of a 240-volt cable, YOU WILL RECEIVE A SHOCK and possibly be electrocuted

-

Electrical Burns

-

Most common shock-related, nonfatal injury

-

Occurs when you touch electrical wiring or equipment that is improperly used or maintained

-

Typically occurs on the hands

-

Very serious injury that needs immediate attention

Falls

-

Electric shock can also cause indirect or secondary injuries

-

Workers in elevated locations who experience a shock can fall, resulting in serious injury or death

Inadequate Wiring Hazards

-

A hazard exists when a conductor is too small to safely carry the current

-

Example: using a portable tool with an extension cord that has a wire too small for the tool

-

The tool will draw more current than the cord can handle, causing overheating and a possible fire without tripping the circuit breaker

-

The circuit breaker could be the right size for the circuit but not for the smaller-wire extension cord

-

Note that wire-gauge size is inversely related to the diameter of the wire. For example, a No. 12 flexible cord has a larger diameter wire than a No. 14 flexible cord.

Overload Hazards

-

If too many devices are plugged into a circuit, the current will heat the wires to a very high temperature, which may cause a fire.

-

If the wire insulation melts, arcing may occur and cause a fire in the area where the overload exists, even inside a wall.

- If the circuit breakers or fuses are too big (high current rating) for the wires they are supposed to protect, an overload in the circuit will not be detected and the current will not be shut off. A circuit with improper overcurrent protection devices – or one with no overcurrent protection devices at all – is a hazard.

Electrical Protective Devices

-

These devices shut off electricity flow in the event of an overload or ground-fault in the circuit

-

Examples include fuses, circuit breakers, and ground-fault circuit-interrupters (GFCI’s)

-

Fuses and circuit breakers are overcurrent devices

-

When there is too much current:

-

Fuses melt

-

Circuit breakers trip open

-

-

The basic idea of an overcurrent device is to make a weak link in the circuit. In the case of a fuse, the fuse is destroyed before another part of the system is destroyed. In the case of a circuit breaker, a set of contacts opens the circuit. Unlike a fuse, a circuit breaker can be re-used by re-closing the contacts. Fuses and circuit breakers are designed to protect equipment and facilities, and in so doing, they also provide considerable protection against shock in most situations. However, the only electrical protective device whose sole purpose is to protect people is the ground-fault circuit-interrupter.

Ground-Fault Circuit Interrupter (GFCI)

-

This device protects you from dangerous shock

-

The GFCI detects a difference in current between the black and white circuit wires

-

This could happen when electrical equipment is not working correctly, causing current “leakage” – known as a ground fault.

-

-

If a ground fault is detected, the GFCI can shut off electricity flow in as little as 1/40 of a second, protecting you from a dangerous shock

-

The GFCI continually matches the amount of current going to an electrical device against the amount of current returning from the device along the electrical path.

-

Whenever the amount of current going differs from the amount returning by approximately 5 milliamperes, the GFCI interrupts the electric power within as little as 1/40 of a second, protecting you from a dangerous shock.

-

GFCI’s are able to detect the loss of current resulting from leakage through a person who is beginning to be shocked. If this situation occurs, the GFCI switches off the current in the circuit.

-

GFCI’s are different from circuit breakers and fuses because they detect leakage currents rather than overloads.

Grounding

-

Grounding Hazards

-

Some of the most frequently violated OSHA standards

-

Metal parts of an electrical wiring system that we touch (switch plates, ceiling light fixtures, conduit, etc.) should be at zero volts relative to ground

-

Housings of motors, appliances or tools that are plugged into improperly grounded circuits may become energized

-

If you come into contact with an improperly grounded electrical device, YOU WILL BE SHOCKED

-

-

-

What is Grounding?

-

Grounding is a physical connection to the earth, which is at zero volts.

-

Current flows through a conductor if there is a difference in voltage (electrical force). If metal parts of an electrical wiring system are at zero volts relative to ground, no current will flow if our body completes the circuit between these parts and ground.

-

Two kinds of grounds are required by the standard:

-

Service or system ground. In this instance, one wire — called the neutral conductor or grounded conductor — is grounded. In an ordinary low-voltage circuit, the white (or gray) wire is grounded at the generator or transformer and again at the service entrance of the building. This type of ground is primarily designed to protect machines, tools, and insulation against damage.

-

For enhanced worker protection, an additional ground, called the equipment ground, must be furnished by providing another path from the tool or machine through which the current can flow to the ground. This additional ground safeguards the electric equipment operator if a malfunction causes the metal frame of the tool to become energized.

-

-

Overhead Powerlines

-

Most people don’t realize that overhead powerlines are usually not insulated

-

Powerline workers need special training and personal protective equipment (PPE) to work safely

-

Do not use metal ladders – instead, use fiberglass ladders

-

Beware of powerlines when you work with ladders and scaffolding

-

Overhead power lines must be deenergized and grounded by the owner or operator of the lines, or other protective measures must be provided, before work is started. Protective measures (such as guarding or insulating the lines) must be designed to prevent contact with the lines.

-

Minimum clearance distances for employees working in the vicinity of overhead power lines are given in 29 CFR 1910.333(c)(3).

-

PPE may consist of rubber insulating gloves, hoods, sleeves, matting, blankets, line hose, and industrial protective helmets.

Examples of OSHA Requirements

Electrical accidents appear to be caused by a combination of three factors:

1. Unsafe equipment and/or installation

2. Workplaces made unsafe by the environment

3. Unsafe work practices

There are various ways of protecting people from the hazards caused by electricity. These include: insulation, guarding, grounding, electrical protective devices, and safe work practices.

GROUNDING PATH

- The path to ground from circuits, equipment, and enclosures must be permanent and continuous

- Violation shown here is an extension cord with a missing grounding prong

HAND-HELD ELECTRICAL TOOLS

- Hand-held electric tools pose a potential danger because they make continuous good contact with the hand

-

To protect you from shock, burns, and electrocution, tools must:

-

Have a three-wire cord with ground and be plugged into a grounded receptacle, or

-

Be double insulated, or

-

Be powered by a low-voltage isolation transformer

-

-

Hazards of portable electric tools:

-

Power drills use 30 times the lethal amount of current

-

Tool is held even more tightly, resulting in longer exposure to shocking current

-

Person cannot release tool

-

Currents as small as 10 mA can paralyze, or “freeze” muscles

-

- Double-insulated equipment must be distinctly marked to indicate that the equipment utilizes an approved system of double insulation.

GUARDING OF LIVE PARTS: OSHA 1910.303(g)(2)(i) and 1910.303(g)(2)(iii)

- Must guard live parts of electric equipment operating at 50 volts or more against accidental contact by:

- Approved cabinets/enclosures, or

- Location or permanent partitions making them accessible only to qualified persons, or

- Elevation of 8 ft. or more above the floor or working surface

- Mark entrances to guarded locations with conspicuous warning signs

- Must enclose or guard electric equipment in locations where it would be exposed to physical damage [OSHA 1910.303(g)(2)(ii)]

- Violation shown here is physical damage to conduit

CABINETS, BOXES AND FITTINGS: OSHA 1910.305(b)(1) and (2)

- Junction boxes, pull boxes and fittings must have approved covers

- Unused openings in cabinets, boxes and fittings must be closed (no missing knockouts)

- Photo shows violations of these two requirements

USE OF FLEXIBLE CORDS: OSHA 1910.305(g)

-

More vulnerable than fixed wiring

-

Do not use if one of the recognized wiring methods can be used instead

-

Flexible cords can be damaged by:

-

Aging

-

Door or window edges

-

Staples or fastenings

-

Abrasion from adjacent materials

-

Activities in the area

-

-

Improper use of flexible cords can cause shocks, burns or fire

-

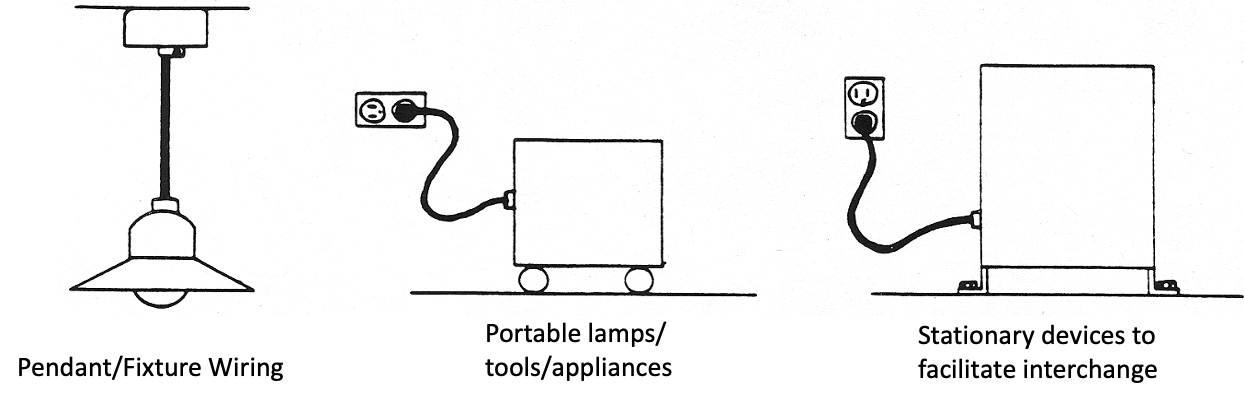

Permissible Uses of Flexible Cords (examples)

- Other Examples (Permissible uses of flexible cords)

-

Elevator cables

-

Wiring of cranes and hoists

-

Prevention of the transmission of noise or vibration

-

Appliances where the fastening means and mechanical connections are designed to permit removal for maintenance and repair

-

Data processing cables approved as part of the data processing system

-

-

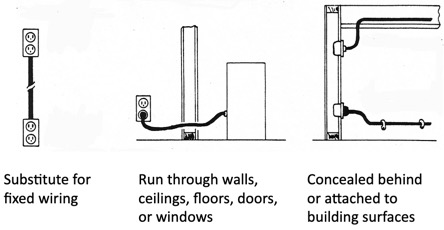

Prohibited Uses of Flexible Cords: OSHA 1910.305(g)(1)(iii)

Clues That Electrical Hazards Exist

-

Tripped circuit breakers or blown fuses

-

Warm tools, wires, cords, connections, or junction boxes

-

GFCI that shuts off a circuit

-

Worn or frayed insulation around wire or connection

Training

- Train employees working with electric equipment in safe work practices, including:

-

Deenergizing electric equipment before inspecting or making repairs

-

The accidental or unexpected sudden starting of electrical equipment can cause severe injury or death. Before ANY inspections or repairs are made the current must be turned off at the switch box and the switch padlocked in the OFF position. At the same time, the switch or controls of the machine or other equipment being locked out of service must be securely tagged to show which equipment or circuits are being worked on.

-

-

Using electric tools that are in good repair

-

Using good judgment when working near energized lines

-

Using appropriate protective equipment

-

NOTE: For more information on the Lockout/Tagout (LOTO) standard, 1910.147, see the Lockout/Tagout Interactive Training Program at the osha web site, www.osha.gov and find this reference under “OSHA Advisors”. OSHA’s electrical safety-related work practice requirements are contained in 29 CFR 1910.331-.335.

Summary

Hazards

-

Inadequate wiring

-

Exposed electrical parts

-

Wires with bad insulation

-

Ungrounded electrical systems and tools

-

Overloaded circuits

-

Damaged power tools and equipment

-

Using the wrong PPE and tools

-

Overhead powerlines

-

All hazards are made worse in wet conditions

Protective Measures

-

Proper grounding

-

Using GFCI’s

-

Using fuses and circuit breakers

-

Guarding live parts

-

Proper use of flexible cords

-

Training

References

OSHA Standard

· 29 CFR 1910 Subpart S (1910.301 to 1910.399)

Ø http://www.osha-slc.gov/OshStd_toc/OSHA_Std_toc_1910_SUBPART_S.html

OSHA Publications

Ø http://www.osha-slc.gov/OshDoc/Additional.html

· 3075 Controlling Electrical Hazards

· 3080 Hand and Power Tools

· 3120 Control of Hazardous Energy (Lockout/Tagout)

OSHA References/Resources

· LOTO Plus Expert Advisor

Ø http://www.osha-slc.gov/dts/osta/oshasoft/lotoplus.html

· OSHA’s Small Business Outreach Training Program, Electrical

Ø http://www.osha-slc.gov/SLTC/smallbusiness/sec14.html

· OSHA Technical Links – Electrical

Ø http://www.osha-slc.gov/SLTC/electrical/index.html

· OSHA Technical Links – Control of Hazardous Energy (Lockout/Tagout)

Ø http://www.osha-slc.gov/SLTC/controlhazardousenergy/index.html

· Self-Inspection Checklists

Ø http://www.osha-slc.gov/SLTC/smallbusiness/chklist.html#Electrical

· Self-Inspection Checklists – Lockout/Tagout Procedures

Ø http://www.osha-slc.gov/SLTC/smallbusiness/chklist.html#Lockout

Course Exam

Before you receive your certificate, you must complete the exam and achieve a score of % or higher. (You have unlimted attempts).

This exam is required by your state licensure.

Exam

Exam

We are required to delay the exam hours. Check back soon!

Exam

We are required to delay the exam until you have had time to view the course material. Please view the course first!

No Licenses on File

Please add a license to your account before you continue. Thank you!