OSHA - Hazard Communication

OSHA - Hazard Communication

Course Description

This course focuses on OSHA's hazard communication standards, and includes topics such as employer responsibilities, written requirements and training.

Accreditation Information: KLA Education Services LLC is accredited by the State of California Board of Registered Nursing, Provider # CEP16145.

Course Certification: Once you have completed this course, click on the “Print Certificate” option below to save or print your CE course certification. If you are not yet registered in a course plan with IvyLeagueNurse, please complete the registration and payment process so that you are able to log into your account and fully obtain your course certificate. Our affordable and unlimited one-year CEU plan starts at just $19.99.

Print Certificate Print Course

Course Objectives

Upon completion of this course, the course participant will be able to:

- Describe the four main employer responsibilities under the HazCom standard.

- Discuss in detail at least 3 components of an appropriate HazCom program, including requirements to provide specific

- Discuss the differences between HazCom labeling requirements for a commercially procured chemical in its original packaging or container, and other workplace chemical containers such as stationary containers, portable containers and piping systems

- Identify at least five pieces of information found on each material safety data sheet.

Course Content

Introduction

-

About 32 million workers work with and are potentially exposed to one or more chemical hazards

-

There are approximately 650,000 existing chemical products, and hundreds of new ones being introduced annually

-

Chemical exposure may cause or contribute to many serious health effects such as heart ailments, central nervous system damage, kidney and lung damage, sterility, cancer, burns, and rashes

-

Some chemicals may also be safety hazards and have the potential to cause fires and explosions and other serious accidents

NOTES:

This is one of the most frequently cited OSHA standards.

This program is intended for workplaces that do not manufacture, import, or distribute hazardous chemicals. Notes have been provided that highlight some of the requirements for these employers. For complete requirements, consult 29 CFR 1910.1200.

Purpose of OSHA’s Hazard Communication Standard

-

To ensure that employers and employees know about work hazards and how to protect themselves so that the incidence of illnesses and injuries due to hazardous chemicals is reduced.

-

The Hazard Communication (HazCom) standard establishes uniform requirements to make sure that the hazards of all chemicals imported into, produced, or used in U.S. workplaces are evaluated, and that this hazard information is transmitted to affected employers and exposed employees.

-

The HazCom standard is different from other OSHA health rules because it covers all hazardous chemicals. The rule also incorporates a “downstream flow of information,” which means that producers of chemicals have the primary responsibility for generating and disseminating information, whereas users of chemicals must obtain the information and transmit it to their employees.

-

The Hazard Communication (HazCom) standard establishes uniform requirements to make sure that the hazards of all chemicals imported into, produced, or used in U.S. workplaces are evaluated, and that this hazard information is transmitted to affected employers and exposed employees.

-

The HazCom standard is different from other OSHA health rules because it covers all hazardous chemicals. The rule also incorporates a “downstream flow of information,” which means that producers of chemicals have the primary responsibility for generating and disseminating information, whereas users of chemicals must obtain the information and transmit it to their employees.

-

Regulatory Reference: OSHA 29 CFR 1910.1200

Who is Covered?

- OSHA’s Hazard Communication (HazCom) standard applies to general industry, shipyard, marine terminals, longshoring, and construction employment and covers chemical manufacturers, importers, employers, and employees exposed to chemical hazards.

- “Hazardous Chemical” is any chemical which is a physical or health hazard.

-

Does the standard apply to an office environment? Office workers who encounter hazardous chemicals only in isolated instances are not covered by the rule. OSHA considers most office products (such as pens, pencils, adhesive tape) to be exempt under the provisions of the rule. OSHA has stated that intermittent or occasional use of a copying machine does not result in coverage under the rule. However, if an employee handles the chemicals to service the machine, or operates it for long periods of time, then the standard would apply.

-

Regulatory reference: OSHA 1910.1200(b)

Employer Responsibilities

-

Identify and list hazardous chemicals in their workplaces

-

Obtain Material Safety Data Sheets (MSDSs) and labels for each hazardous chemical, if not provided by the manufacturer, importer, or distributor

-

Implement a written HazCom program, including labels, MSDSs, and employee training

-

Communicate hazard information to employees through labels, MSDSs, and formal training programs

How Can Workplace Hazards Be Minimized?

-

The first step in minimizing workplace hazards is to perform a thorough hazard assessment

-

Employers can rely on the evaluations performed by the manufacturers or importers to establish the hazards of the chemicals they use

-

This information is obtained from material safety data sheets (MSDSs) and labels.

-

NOTE: Chemical manufacturers and importers must review scientific evidence on the hazards of chemicals they produce or import and report findings to their employees and to employers who distribute or use their products.

Why is a written program required?

-

Ensures that all employers receive the information they need to inform and train their employees

-

Provides necessary hazard information to employees

-

Regulatory reference: OSHA 1910.1200(e)

Written HazCom Program

- Requirements

-

Describes container labeling, MSDSs, and employee training for each workplace

-

List of the hazardous chemicals

-

Make information regarding hazards and protective measures available to other employers onsite

-

Employer also required to describe how they will inform employees of the hazards of non-routine tasks (for example, cleaning reactor vessels), and the hazards associated with chemicals in unlabeled pipes

-

How Must Chemicals Be Labeled?

-

Each container of hazardous chemicals entering the workplace must be labeled or marked with:

-

Identity of the chemical

-

Appropriate hazard warnings

-

Name and address of the responsible party

-

-

Chemical manufacturers and importers must convey the hazard information to downstream employers by means of labels on containers and Material Safety Data Sheets (MSDSs). Language used on the warning label does not have to be identical to that on the MSDS.

-

Chemical manufacturers, importers, and distributors must be sure that containers of hazardous chemicals leaving the workplace are labeled, tagged, or marked with:

-

the identity of the chemical

-

appropriate hazard warnings

-

the name and address of the chemical manufacturer, importer, or other responsible party

-

-

Consumer products having labels meeting requirements of the Consumer Product Safety Act do not have to have additional labeling under the HazCom Standard.

-

Regulatory reference: OSHA 1910.1200(f)

Container Labeling in the Workplace

-

The hazard warning can be any type of message, picture, or symbol that provides information on the hazards of the chemical(s) and the targeted organs affected, if applicable

-

Labels must be legible, in English (plus other languages, if desired), and prominently displayed

-

Exceptions to container labeling requirements:

-

Can post signs/placards that convey hazard information if there are a number of stationary containers within a work area with similar contents and hazards

-

Can substitute various types of standard operating procedures, process sheets, and similar written materials for container labels on stationary process equipment if they contain the same information and are readily accessible to employees in the work area

-

Not required to label portable containers into which hazardous chemicals are transferred from labeled containers and are intended only for the immediate use of the employee who makes the transfer

-

Pipes or piping systems, and engines, fuel tanks, or other operating systems in a vehicle, are not considered to be containers.

-

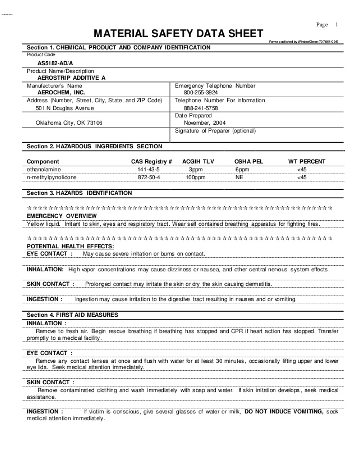

Material Safety Data Sheet (MSDS)

- Prepared by the chemical manufacturer or importer and describe:

-

Physical hazards, such as fire and explosion

-

Health hazards, such as signs of exposure

-

Routes of exposure

-

Precautions for safe handling and use

-

Emergency and first-aid procedures

-

Control measures

-

-

Chemical manufacturers and importers must develop an MSDS for each hazardous chemical they produce or import, and must provide the MSDS at the time of the initial shipment to a downstream distributor or user. Distributors also must ensure that downstream employers are similarly provided an MSDS.

-

The MSDSs must be updated by the chemical manufacturer or importer within three months of learning of "new or significant information" regarding the chemical's hazard potential.

-

OSHA does not require that MSDSs be provided to purchasers of household consumer products (such as "windex" and "white‑out“) when the products are used in the workplace in the same manner that a consumer would use them, i.e.; where the duration and frequency of use (and therefore exposure) is not greater than what the typical consumer would experience. Employees who are required to work with hazardous chemicals in a greater duration and frequency of exposure than a normal consumer have a right to know about the properties of those hazardous chemicals.

-

Regulatory Reference: OSHA 1910.1200(g)

Material Safety Data Sheet (cont’d)

-

Must be in English and include information regarding the specific chemical identity and common names

-

Must provide information about the:

-

Physical and chemical characteristics

-

Health effects

-

Exposure limits

-

Carcinogenicity (cancer-causing)

-

Identification (name, address, and telephone number) of the organization responsible for preparing the sheet

-

-

Must be readily accessible to employees in their work area

-

In the absence of other employee exposure records, MSDSs that indicate a health hazard are considered employee exposure records under the Access to Employee Medical Records standard, 29 CFR 1910.1020 and must be preserved and maintained for at least thirty years, with some exceptions.

-

Electronic access is acceptable provided:

-

A back-up procedure is available if the electronic system fails

-

It can be accessed in the employee’s work area

-

-

The telephone number provided must be that of a person who can provide additional information about the hazardous chemical and appropriate emergency procedures.

-

Regulatory Reference: 29 CFR 1910.1020(d)

Material Safety Data Sheet (cont’d)

-

MSDSs have no prescribed format

-

If no MSDS has been received for a hazardous chemical, employer must contact the supplier, manufacturer, or importer to obtain one and maintain a record of the contact

-

One MSDS may apply to multiple complex mixtures having similar contents and hazards.

-

For information regarding the preparation of MSDSs, see ANSI Z400.1, Hazardous Industrial Chemicals – Material Safety Data Sheets – Preparation

Training

-

Training is required for employees who are exposed to hazardous chemicals in their work area:

-

At the time of initial assignment

-

Whenever a new hazard is introduced into their work area

-

-

Training is not satisfied solely by giving the employee the data sheets to read. An employer's training program is to be a forum for explaining to employees not only the hazards of the chemicals in their work area, but also how to use the information generated in the hazard communication program. This can be accomplished in many ways (audiovisuals, classroom instruction, interactive video), and should include an opportunity for employees to ask questions to ensure that they understand the information presented to them. Training must be carried out in a language that is comprehensible to the employees.

-

Training need not be conducted on each specific chemical found in the workplace, but may be conducted by categories of hazard (e.g., carcinogens, sensitizers, acutely toxic agents, irritants, flammables) that are or may be encountered by an employee during the course of his duties.

-

Regulatory reference: OSHA 1910.1200(h)

What training is needed to protect workers?

-

Explanation of the HazCom program, including information on labels, MSDSs, and how to obtain and use available hazard information

-

Hazards of chemicals

-

Protective measures such as engineering controls, work practices, and the use of PPE

-

How to detect the presence or release of a hazardous chemical (using monitoring devices, observation, or smell)

What information must be provided to workers?

-

Employees must be informed of:

-

The HazCom standard and its requirements

-

Operations in their work areas where hazardous chemicals are present

-

Location and availability of the written hazard evaluation procedures, communications program, lists of hazardous chemicals, and the required MSDSs

-

Summary

-

OSHA’s Hazard Communication Standard is based on a simple concept - that employees have both a need and a right to know the hazards and identities of the chemicals they are exposed to when working.

-

Employees also need to know what protective measures are available to prevent adverse effects from occurring.

-

See www.osha.gov for more information on hazard communication, including the following publications:

-

Hazard Communication Guidelines for Compliance – OSHA 3111 ; (This is the same information that is contained in Appendix E to 1910.1200 and is also available in Spanish.)

-

Chemical Hazard Communication – OSHA 3084 ; (This is also available in Spanish.)

-

Course Description

Course Objectives

Course Content

- Introduction

- Purpose of OSHA’s Hazard Communication Standard

- Who is Covered?

- Employer Responsibilities

- How Can Workplace Hazards Be Minimized?

- Why is a written program required?

- Written HazCom Program

- How Must Chemicals Be Labeled?

- Container Labeling in the Workplace

- Material Safety Data Sheet (MSDS)

- Material Safety Data Sheet (cont’d)

- Material Safety Data Sheet (cont’d)

- Training

- What training is needed to protect workers?

- What information must be provided to workers?

- Summary

Course Exam

Before you receive your certificate, you must complete the exam and achieve a score of % or higher. (You have unlimted attempts).

This exam is required by your state licensure.

Exam

Exam

We are required to delay the exam hours. Check back soon!

Exam

We are required to delay the exam until you have had time to view the course material. Please view the course first!

No Licenses on File

Please add a license to your account before you continue. Thank you!