OSHA - Flammable and Combustible Liquids

OSHA - Flammable and Combustible Liquids

Course Description

This course presents OSHA standards regarding flammable and combustible liquids, and addresses the primary concerns of design and construction, ventilation, ignition sources and storage.

Accreditation Information: KLA Education Services LLC is accredited by the State of California Board of Registered Nursing, Provider # CEP16145.

Course Certification: Once you have completed this course, click on the “Print Certificate” option below to save or print your CE course certification. If you are not yet registered in a course plan with IvyLeagueNurse, please complete the registration and payment process so that you are able to log into your account and fully obtain your course certificate. Our affordable and unlimited one-year CEU plan starts at just $19.99.

Print Certificate Print Course

Course Objectives

Upon completion of this course, the course participant will be able to:

- Define flash point, flammable liquid, and combustible liquid.

- Explain at least 2 ways to avoid explosion or fire from flammable or combustible liquids

- List 4 potential sources of ignition for flammable and combustible liquids.

- Identify at least 2 actions that apply to each of the 4 components of a good plan for safe use of flammable and combustible liquids.

Course Content

Introduction

-

The two primary hazards associated with flammable and combustible liquids are explosion and fire

-

Safe handling and storage of flammable liquids requires the use of approved equipment and practices per OSHA standards

-

Regulation: 29 CFR 1910.106

Flash Point

-

Flash point means the minimum temperature at which a liquid gives off enough vapor to form an ignitable mixture

-

In general, the lower the flash point, the greater the hazard

-

Flammable liquids have flash points below 100oF, and are more dangerous than combustible liquids, since they may be ignited at room temperature

-

Flammable liquids themselves will not burn, but as the liquid evaporates, it gives off vapors that mix with the air to form dangerous gases that can be set off by a small spark. Gasoline, for example, evaporates at temperatures as low as 45 degrees Fahrenheit below zero. As the temperature rises, the rate of evaporation increases and more and more vapors are given off. Flammable vapors are usually heavier than air so they collect in the lowest areas they can reach. Without good ventilation to dissipate them, a small spark can set off a big disaster.

-

-

Combustible liquids have flash points at or above 100oF

-

Although combustible liquids have higher flash points than flammable liquids, they can pose serious fire and/or explosion hazards when heated

Classes of Flammable and Combustible Liquids

- Regulation: 1910.106(a)(18) and (19)

- Flammable and combustible liquids are classified primarily according to their flash point to indicate the danger they pose as a fire hazard. Flash point is directly related to a liquid’s ability to generate vapor. Since it is the vapor of a liquid, not the liquid itself, that burns, vapor generation becomes a primary factor in determining the fire hazard.

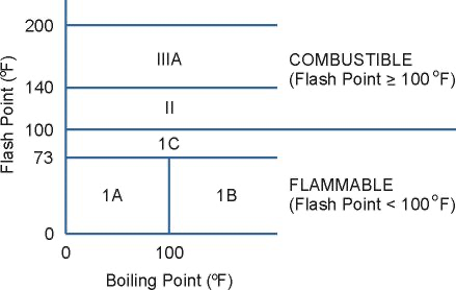

- Flammable liquids have flash points below 100oF and are classified as Class I liquids. Flammable liquids are sub-divided into three subclasses: IA, IB, and IC. Class IA liquids have flash points below 73oF and boiling points below 100oF. Class 1B liquids have flash points below 73oF and boiling points at or above 100oF. Class IC liquids have flash points at or above 73oF and below 100oF.

- Combustible liquids have flash points at or above 100oF and are classified as Class II and Class III liquids. Class II liquids have flash points at or above 100oF and below 140oF. Class III liquids are sub-divided into two subclasses: IIIA and IIIB. Class IIIA liquids have flash points at or above 140oF and below 200oF. Class IIIB liquids have flash points at or above 200oF, and are not regulated by 1910.106.

Classes & Examples of Some Flammable Liquids

|

Class |

Common Name |

Flash Point (°F) |

|

IA |

ETHYL ETHER |

-49 |

|

IA |

PENTANE |

< -40 |

|

IB |

GASOLINE |

-45 |

|

IB |

METHYL ETHYL KETONE |

21 |

|

IB |

TOLUENE |

40 |

|

IB |

ACETONE |

0 |

|

IB |

VM&P NAPTHA |

2—45 (TYPICAL) |

|

IB |

ETHYL ALCOHOL |

55 |

|

IC |

MINERAL SPIRITS |

85-110 |

|

IC |

XYLENE |

81-115 |

|

IC |

TURPENTINE |

95 |

|

II |

FUEL OILS |

100-130 |

|

II |

KEROSENE |

110-150 |

|

III |

ETHYLENE GLYCOL |

232 |

Program Components

A good plan for safe use of flammable and combustible liquids contains at least these components:

-

Control of ignition sources

-

Proper storage

-

Fire control

-

Safe handling

Sources of Ignition

Must take adequate precautions to prevent ignition of flammable vapors. Some sources of ignition include:

-

Open flames

-

Smoking

-

Static electricity

-

Cutting and welding

-

Hot surfaces

-

Electrical and mechanical sparks

-

Lightning

-

Reference: 1910.106(e)(6)(i)

Static Electricity

-

Can be generated by the contact and separation of dissimilar materials. Examples include:

-

fluid flowing through pipe or from an opening into a tank

-

operation of belts and pulleys

-

splash filling of flammable liquids

-

agitation and mixing of fluids

-

tires on the roadway

-

-

Main hazards are fire and explosion from sparks containing enough energy to ignite flammable vapors

-

Bonding or grounding of flammable liquid containers is necessary to prevent static electricity from causing a spark

-

Notes:

-

For more information, see NFPA 77, Static Electricity.

-

One of the primary means of reducing the hazard of static electricity when transferring flammable liquids into/from containers is through the use of bonding and grounding, which is discussed in this program.

-

Bonding

-

Physically connect two conductive objects together with a bond wire to eliminate a difference in static charge potential between them

-

Must provide a bond wire between containers during flammable liquid filling operations, unless a metallic path between them is otherwise present

-

Both objects bonded share the same charge and have no potential difference, BUT there still is a potential difference between the conductive objects and ground. Thus, there is danger of a spark from one of the conductive objects to grounded objects.

-

Regulatory reference: 1910.106(e)(6)(ii)

Grounding

-

Eliminates a difference in static charge potential between conductive objects and ground

-

Although bonding will eliminate a difference in potential between objects, it will not eliminate a difference in potential between these objects and earth unless one of the objects is connected to earth with a ground wire

-

Both objects bonded and grounded permit charge to flow to ground.

-

Regulatory reference: 1910.106(e)(6)(i)

Ventilation

- Always provide adequate ventilation to reduce the potential for ignition of flammable vapors.

- Ventilation for the prevention of fire and explosion is considered adequate if it is sufficient to prevent accumulation of significant quantities of vapor-air mixtures in concentration over one-fourth of the lower flammable limit.

- Regulatory reference: 1910.106(a)(31)

Storage Fundamentals

-

Identify incompatible chemicals – check the Material Safety Data Sheet

-

Isolate and separate incompatible materials

-

Isolate by storing in another area or room

-

Degree of isolation depends on quantities, chemical properties and packaging

-

Separate by storing in same area or room, but apart from each other

-

Storage of Flammable and Combustible Liquids

-

Storage must not limit the use of exits, stairways, or areas normally used for the safe egress of people

-

In office occupancies:

-

Storage prohibited except that which is required for maintenance and operation of equipment

-

Storage must be in:

-

closed metal containers inside a storage cabinet, or

-

safety cans, or

-

an inside storage room

-

must not have a door that opens into that portion of the building used by the public

-

-

-

Regulatory reference: 1910.106(d)(5)(i) and (iii)

Safety Cans for Storage and Transfer

-

Approved container of not more than 5 gallons capacity

-

Spring-closing lid and spout cover

-

Safely relieves internal pressure when exposed to fire

-

Regulatory reference: 1910.106(a)(29)

Flame Arrester Screen

-

Prevents fire flashback into can contents

-

Double wire-mesh construction

-

Large surface area provides rapid dissipation of heat from fire so that vapor temperature inside can remains below ignition point

Storage Cabinets

-

Not more than 60 gal of Class I and/or Class II liquids, or not more than 120 gal of Class III liquids permitted in a cabinet

-

Must be conspicuously labeled, “Flammable - Keep Fire Away”

-

Doors on metal cabinets must have a three-point lock (top, side, and bottom)

-

prevents buckling, which would expose contents to fire

-

-

door sill must be raised at least 2 inches above the bottom of the cabinet (contains leaks)

Fire Control

-

Suitable fire control devices, such as small hose or portable fire extinguishers must be available where flammable or combustible liquids are stored

-

Open flames and smoking must not be permitted in these storage areas

-

Materials which react with water must not be stored in the same room with flammable or combustible liquids

-

Regulatory reference: 1910.106(d)(7)(i) and (iii) and (iv)

Transferring Flammable Liquids

- Because there is a sizeable risk whenever flammable liquids are handled, OSHA allows only four methods for transferring these materials:

-

Through a closed piping system

-

From safety cans

-

By gravity through an approved self-closing safety faucet

-

By means of a safety pump

-

-

Note: Transferring of flammable liquids by means of air pressure on the container or portable tanks is prohibited.

-

Regulatory reference: 1910.106(e)(2)(iv)(d)

Self-Closing Safety Faucet

-

Bonding wire between drum and container

-

Grounding wire between drum and ground

-

Safety vent in drum

Safety Pump

-

Faster and safer than using a faucet

-

Spills less likely

-

No separate safety vents in drum required

-

Installed directly in drum bung opening

-

Some pump hoses have integral bonding wires

Waste and Residue

- Combustible waste and residue must be kept to a minimum, stored in covered metal receptacles and disposed of daily.

- Regulatory reference: OSHA 1910.106(e)(9)(iii)

Waste Drum with Disposal Funnel

Safety Disposal Can

Oily-Waste Can (self-closing lid)

Safe Handling Fundamentals

-

Carefully read the manufacturer’s label on the flammable liquid container before storing or using it

-

Practice good housekeeping in flammable liquid storage areas

-

Clean up spills immediately, then place the cleanup rags in a covered metal container

-

Only use approved metal safety containers or original manufacturer’s container to store flammable liquids

-

Keep the containers closed when not in use and store away from exits or passageways

-

Use flammable liquids only where there is plenty of ventilation

-

Keep flammable liquids away from ignition sources such as open flames, sparks, smoking, cutting, welding, etc.

-

In the case of spills or leaks...First, eliminate all sources of ignition. Then:

-

Stop the leak if possible

-

Contain the material

-

Isolate the area

-

Avoid direct contact with the material

-

Use appropriate fire control procedures

-

Summary

-

The two primary hazards associated with flammable and combustible liquids are explosion and fire

-

Safe handling and storage of flammable liquids requires the use of approved equipment and practices per OSHA standards

-

An excellent reference on this topic is National Fire Protection Association Standard No. 30, Flammable and Combustible Liquids Code

Course Description

Course Objectives

Course Content

- Introduction

- Flash Point

- Classes of Flammable and Combustible Liquids

- Classes & Examples of Some Flammable Liquids

- Program Components

- Sources of Ignition

- Static Electricity

- Bonding

- Grounding

- Ventilation

- Storage Fundamentals

- Storage of Flammable and Combustible Liquids

- Safety Cans for Storage and Transfer

- Flame Arrester Screen

- Storage Cabinets

- Fire Control

- Transferring Flammable Liquids

- Self-Closing Safety Faucet

- Safety Pump

- Waste and Residue

- Safe Handling Fundamentals

- Summary

Course Exam

Before you receive your certificate, you must complete the exam and achieve a score of % or higher. (You have unlimted attempts).

This exam is required by your state licensure.

Exam

Exam

We are required to delay the exam hours. Check back soon!

Exam

We are required to delay the exam until you have had time to view the course material. Please view the course first!

No Licenses on File

Please add a license to your account before you continue. Thank you!